Sapwood vs Heartwood

Published: 27/09/19 By: Mike Bekin

Trees are comprised of both sapwood and heartwood. You may have heard of these terms, but here we discuss in further detail what exactly they are, what the difference between the two are, how you can identify each type and how their varying properties affect how you work with the wood.

The Parts of the Tree

Understanding the different parts that comprise the tree can help you with your future wood construction projects immensely. Having this knowledge can ensure you choose the correct wood for your project.

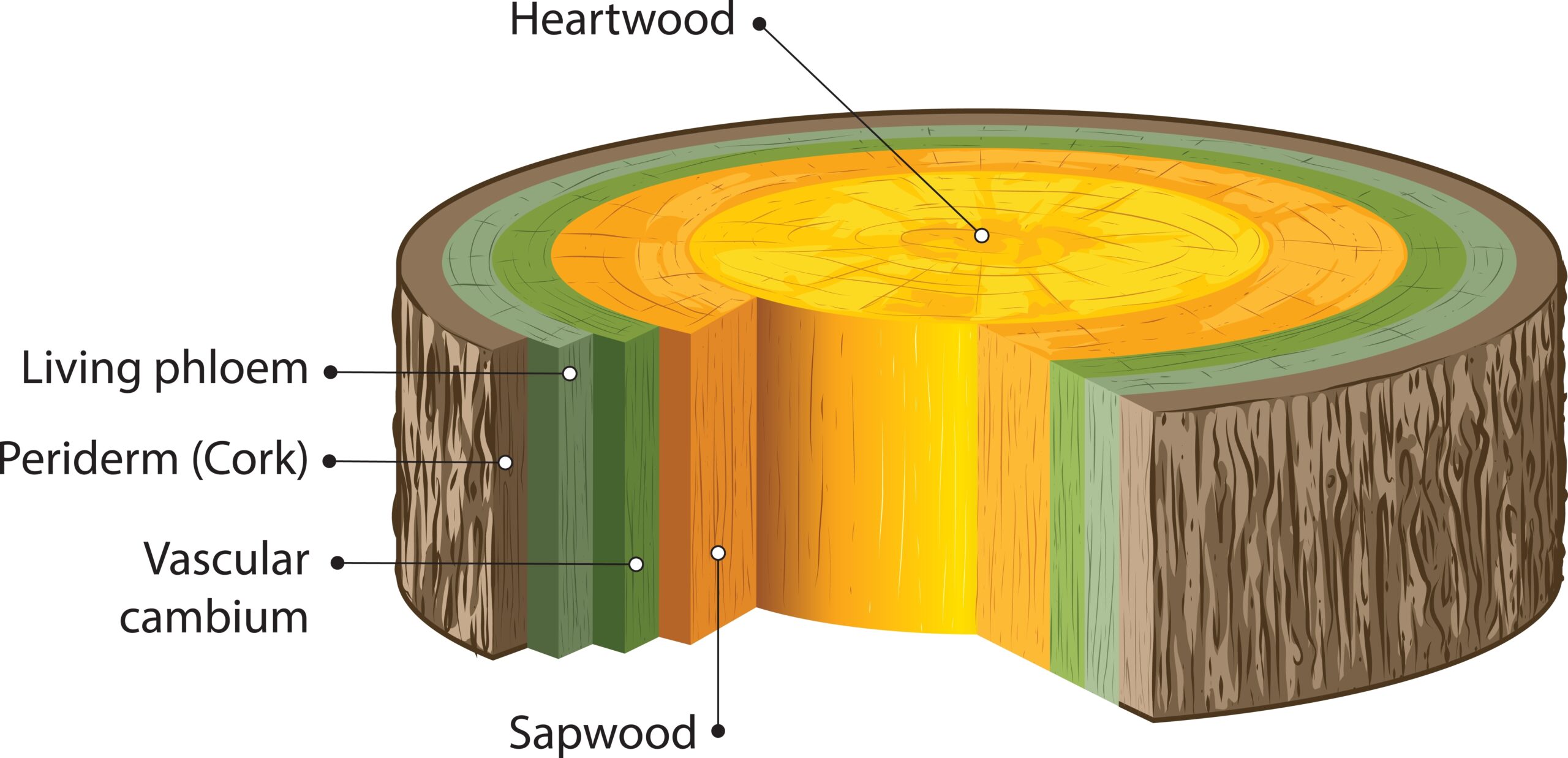

The Bark/Periderm – this outer shell of the tree is in fact dead tissue. Its function is to protect the tree from weather, insects, fires and other potential dangers.

The Phloem – this is the next layer. It is a thin layer of living cells and its function is to transport food and water around the rest of the tree.

The Cambium – next is the cambium. Living tissue that produces new phloem on one side and new xylem on the other

The Xylem – this is the largest part of the tree and is made up of both sapwood and heartwood.

• Sapwood -You can typically identify the sapwood in a tree as it is lighter in colour. This is new wood and is used to move water throughout the tree up to the leaves. Excess food is often stored here as well.

• Heartwood – As the tree ages and a new ring of sapwood is grown, the inner cells are no longer in use and they become heartwood. This creates a strong structural pillar in the core of the tree, allowing it to grow taller each year, in its search for more sunlight. If the outer layers of the tree remain intact, the heartwood will not decay, even though it is dead and retired sapwood. Some believe heartwood must be the most important part of the tree due to the fact that it is called “heart”. However, the name just refers to the central position of the heartwood in the tree. Because the pores are no longer needed in this part of the tree, they are filled with organic matter along with chemicals called extractives which changes the look and other properties of the wood so it becomes stiffer and more durable. Interestingly, some trees never form any heartwood at all, for example, the evergreen tropical devil’s tree.

Differences between Sapwood and Heartwood

Colour – To most woodworkers, it is the colour of the heartwood which is a major benefit. Whereas sapwood tends to range from whitish and cream to yellow and light tan, heartwood can range from rich brown to deep reds and purple hues, which are usually desirable. However, this is not always the case. With some heartwood, such as Spruce (a common softwood species – please see our blog on the differences between hardwoods and softwoods by clicking here), there is not much difference in colour between its sapwood and heartwood. Conversely, the colour of heartwood is not always preferred for all projects. For maple flooring or some pine furnishing, the whiter sapwood is often more sought after.

Treatment- When the heartwood extractives change the wood’s structure, it can reduce the permeability of the wood tissue, making it harder for treatments and chemical preservatives to penetrate this type of wood. Sapwood, on the other hand, can take to chemical treatments well since it was still engaged in transporting nutrients up and down the tree trunk.

Weight- Extractives in the heartwood can often make this type of wood more stable and denser. The weight can be changed during the transformation process if the organic material that plugs the pores is less soluble. This is the case in rosewood where up to 15% additional weight can be added!

Moisture Content – Because sapwood is a living part of the tree, water and sap are flowing through it, meaning its moisture content is a lot higher than heartwood. Although this helps chemical treatments to be absorbed better, it also means that this type of wood is more susceptible to shrinkage once it is dried.

Decay Resistance – Sapwood is not usually resistant to fungi, and resistance tends to only take place in the heartwood section of the tree. Having said this, some wood species such as Cedar and Rosewood are naturally decay-resistant and will automatically be less susceptible to rot than other species such as Spruce or Pine. The most resistant part of the tree still remains the heartwood though.

Appearance – Colour is not the only physical difference between the two types of wood. Because sapwood is part of the outer layer of the tree, it tends to have less knots and markings than heartwood. This makes heartwood the preferred choice sometimes when people are specifically looking for these unique markings as part of their project.

Strength – Many believe that heartwood will be, by default, a lot stronger, but this is not necessarily the case. Many studies have shown that the basic strength of the wood does not change when sapwood transforms into heartwood. Heartwood is known to be more durable, however.

How to know which type to use for your project?

Now that the differences have been highlighted, it is understandable why heartwood is often the preferred option for many woodwork projects: appealing colour, increased stability and durability and lower moisture levels than the sapwood part. However, this is not saying that there is not a place for sapwood to be used for projects. Many woodworkers solely use heartwood, but if used in small areas of the project and thoroughly treated, then there are still uses for sapwood. Whether you are working with sapwood or heartwood, the key factor is to ensure you are using the type of wood that has the correct moisture content you need. By using an accurate moisture meter, you can ensure the wood you are installing is up to scratch and suitable for your project.

Before starting your project, ask yourself the following questions:

1) Is the product you are planning to buy formed from sapwood or heartwood and which species is it?

2) How was the product dried?

3) What is the moisture content?

4) From the answers to the questions above, is this suitable for your project?

Who are EcoChoice?

EcoChoice are specialist suppliers of certified timber and recycled plastic products for exterior works: from cladding and decking to piers and footbridges. We were formed in 2005 with the aim of promoting FSC certified timbers to the UK construction industry, helping customers to engage in a sustainable way instead of turning away from both the deforestation and plastic waste problems. We offer products from a wide range of timber species.

We are passionate about supplying our clients with independently certified timber products while encouraging responsible and sustainable practices at the source level. To find out how we can help you get a quick, no-obligation quote, please call us on 0345 638 1340, email us on info@ecochoice.co.uk or for more information about our sustainable timber products, please visit our website, https://slow.ecochoice.co.uk.